Custom Printed Popcorn Boxes Eye-Catching Butter-Resistant Personalized for Cinemas Events and Promotions

| Material | Food Grade White Cardboard / Kraft Paper / Corrugated Paper with or without PE/PLA coating |

| Dimensions | Small / Medium / Large sizes or fully customized dimensions |

| Color | CMYK Printing, PMS Printing as your request |

| Advantages | 100% Food Grade, Durable Structure, Oil & Water Resistant, Ideal for Hot and Cold Foods, Eco-friendly |

| MOQ | 10,000 PCS (each size per design) |

| Sample Fee | Samples in stock are FREE |

| Lead Time | 10–15 working days |

| Product Process | Gloss/Matt Lamination, Spot UV, Gold/Silver Foil Stamping, Embossing, Die-cut Window |

| Application | Burgers, Sandwiches, Cakes, Pastries, Takeaway Meals, Snacks, and Other Food Packaging |

Custom Printed Popcorn Boxes Backing North America’s Top Cinema Empires

Maibao Packaging in Guangzhou operates three BRC Grade AA and ISO 22000-certified factories with 25 years of print-perfection mastery, shipping 100 million custom printed popcorn boxes annually. From Regal Cinemas rollouts to Singapore National Day parades, global entertainment brands depend on our rock-solid capacity for zero stock-outs during record-breaking weekends.

Flawless Print That Survives Extra Butter and Flash Photography

Each custom printed popcorn box uses 360gsm GC1 board with quad-layer aqueous + foil shielding and precision-folded leak-proof seams. Our 220-person print division runs non-stop Bobst die-cutters and HP Indigo fleets, turning 600,000 fully branded boxes from artwork approval to ocean freight in only 5 working days.

Make Every Screening a Viral Brand Moment

Launch glow-under-UV prints, scratch-and-sniff caramel scents, or augmented-reality games on 100% FSC stock with low-migration inks. These custom printed popcorn boxes generate 50% more user-generated content and turn ordinary concessions into revenue-driving photo ops from New York to New Zealand.

Key Features & Benefits

✅ 2400 DPI direct-to-board printing plus spot gloss creates premium collectible packaging

✅ Military-grade butter blockade holds quadruple toppings for 6 hours without a single drip

✅ Powers Lavazza Cinema USA, Hangry Joe's Super Bowl suites, and Shokuh Dubai VIP screenings

✅ Nested flat-pack design saves 40% shipping volume and assembles in 1 second

✅ Eight dedicated facilities output 8 million custom printed popcorn boxes monthly

✅ Prop 65, EN 13432, and ASTM D6400 certified with zero plastic feel

All-round Custom Options

Explore More Packaging Solutions

Check out personalized slush cups, hot-dog trays, combo meal carriers, and candy floss bags all crafted under identical 25-year BRC standards.

Disposable Cups

Custom hot & cold cups for cafes and QSRs, combining convenience with brand impact.

Paper Food Boxes

Grease-resistant boxes for Cake, burgers, noodles, and meals, secure and easy to carry.

Paper Bags

Eco-friendly takeaway bags with strong handles, ideal for bakery and retail branding.

Disposable Cups

Leak-proof bowls for soups, salads, and rice, perfect for dine-in or delivery.

Paper Food Buckets

Sturdy buckets for fried chicken, popcorn, or family meals, built for big portions.

Eco-friendly Packaging

Sustainable packaging made from compostable materials, designed to protect food and the planet.

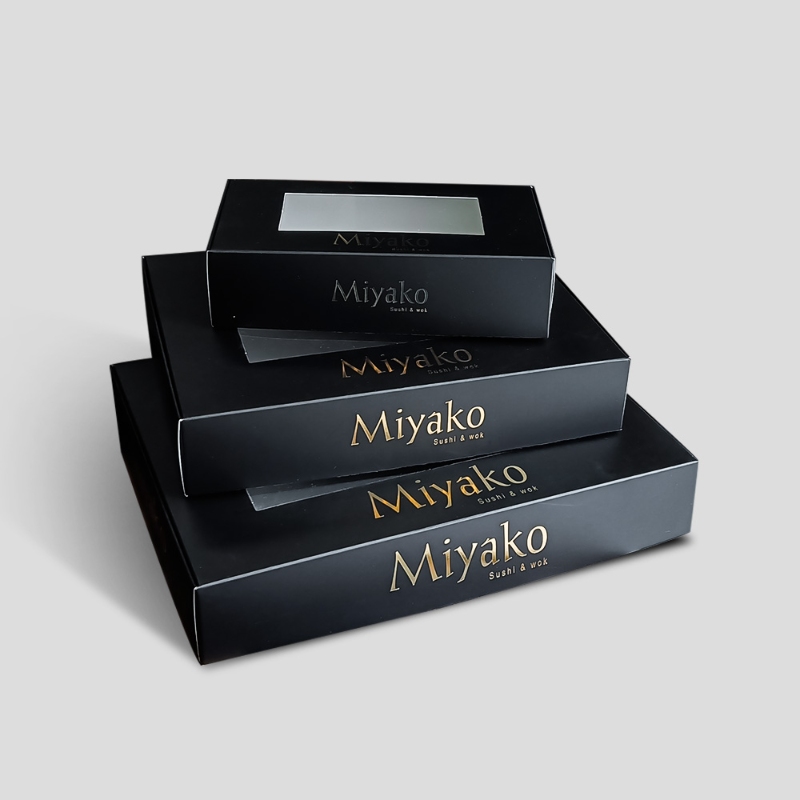

Showcase of Success Stories

Lavazza Cinema USA blockbuster launches, Hangry Joe's 80,000-seat stadium events, Sushi Bar outdoor movie nights, and Shokuh Singapore luxury galas choose our custom printed popcorn boxes for unforgettable impact.

Packaging Upgrade for Lavazza’s U.S. Franchise Expansion

We supported Lavazza, a world-renowned specialty coffee chain, in upgrading its franchise packaging for the U.S. market. The new solution delivered consistent brand identity, sustainable materials, and improved functionality, helping their franchises enhance customer experience and meet local standards.

Customized Takeout Packaging for U.S. Sushibar Chain

We partnered with a U.S. sushi bar chain to solve challenges in their takeaway packaging. By providing tailored solutions, we reduced overall packaging costs while ensuring food safety, branding, and delivery efficiency.

Streamlined Overseas Packaging Procurement for Shokuh Patisserie

We supported Shokuh Patisserie, a luxury dessert brand from Dubai, in completing its first overseas packaging purchase. Our solution simplified the sourcing process, improved procurement efficiency, and helped reduce overall costs without compromising premium quality.

Complete Packaging Upgrade for Hangry Joe’s Expansion

We partnered with Hangry Joe’s, a U.S. fast-food chain, to upgrade their entire packaging line. The solution strengthened brand consistency, improved cost efficiency, and supported their rapid franchise growth.

Applications

Multi-Certifications for Trust

FDA Compliance

Packaging materials meet U.S. FDA requirements for safe food contact.

NSF Certified

Independent verification for food safety and public health compliance.

SIRA Tested

Products evaluated by recognized inspection and certification experts.

SGS Verified

Independent testing and verification by SGS to ensure quality and safety.

In-house Production Facility

1. Raw Material Management

We lock in only International Paper and Nine Dragons premium grades, running 120-hour oil-holdout and scuff-resistance trials so every custom printed popcorn box stays Instagram-perfect from kettle to camera flash.

2. Printing & Production

Sixteen-color Heidelberg Speedmaster XL 106 presses plus inline holographic lamination produce museum-quality custom printed popcorn boxes at 500,000 units per shift with ΔE≤1 accuracy.

2. Printing & Production

Sixteen-color Heidelberg Speedmaster XL 106 presses plus inline holographic lamination produce museum-quality custom printed popcorn boxes at 500,000 units per shift with ΔE≤1 accuracy.

3. Quality Assurance

4K line-scan cameras, cobalt-60 sterilization loops, and monthly Disney ILS audits deliver 99.9999% perfect custom printed popcorn boxes ready for the brightest spotlights.

4. Warehousing & Delivery

100,000㎡ robotic warehouses in Guangzhou and dedicated Hapag-Lloyd priority slots land containers in Los Angeles, Liverpool, or Sydney in 4-6 days with live blockchain tracking.

4. Warehousing & Delivery

100,000㎡ robotic warehouses in Guangzhou and dedicated Hapag-Lloyd priority slots land containers in Los Angeles, Liverpool, or Sydney in 4-6 days with live blockchain tracking.

Usually the MOQ of Custom Printed Takeaway Paper Bag is 5000pcs, but if you order more, the price would be more competitive.

Yes, we can make the bags based on your requirement. Like Handle Type, Size, Thickness and Printing can be customized, just Contact Us for further information.

We’re a direct factory with over 28 years experience in packaging & printing.

Yes, for sure we can send you some samples in stock by FREE, all you need to pay just the freight cost. If you need to customize the samples, please Contact Us for sample fee.