Fast Food Burger Box Grease-Proof Customizable Microwave-Safe for QSR and Delivery Chains

| Material | Food Grade White Cardboard / Kraft Paper / Corrugated Paper with or without PE/PLA coating |

| Dimensions | Small / Medium / Large sizes or fully customized dimensions |

| Color | CMYK Printing, PMS Printing as your request |

| Advantages | 100% Food Grade, Durable Structure, Oil & Water Resistant, Ideal for Hot and Cold Foods, Eco-friendly |

| MOQ | 10,000 PCS (each size per design) |

| Sample Fee | Samples in stock are FREE |

| Lead Time | 10–15 working days |

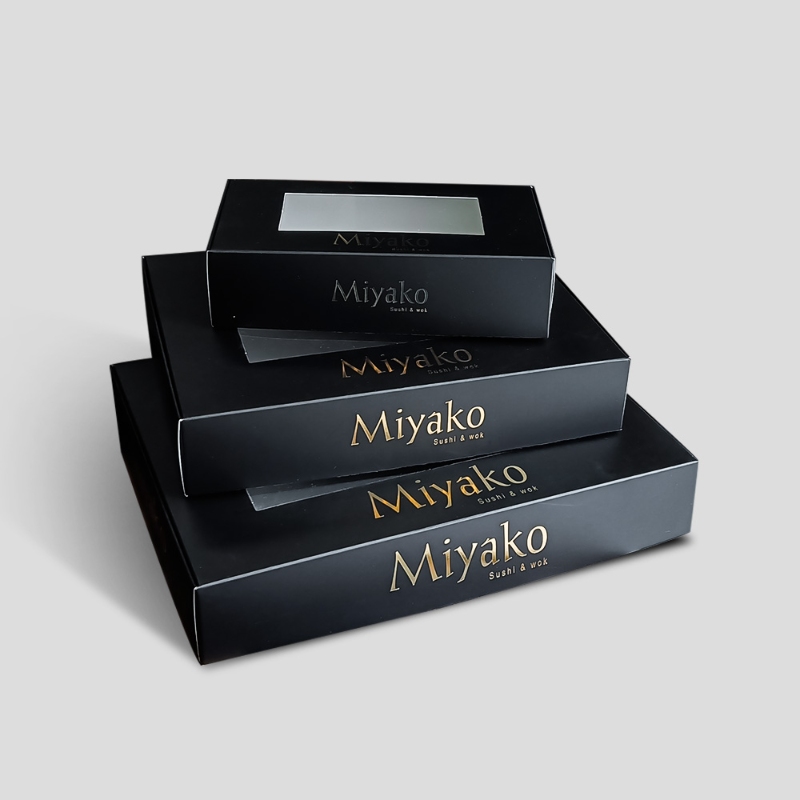

| Product Process | Gloss/Matt Lamination, Spot UV, Gold/Silver Foil Stamping, Embossing, Die-cut Window |

| Application | Burgers, Sandwiches, Cakes, Pastries, Takeaway Meals, Snacks, and Other Food Packaging |

Fast Food Burger Box Engineered for America’s Top Burger Franchises

Maibao Packaging in Guangzhou operates three BRC Grade AA and ISO 22000-certified factories with 25 years of burger packaging mastery, producing 70 million fast food burger boxes annually. Leading U.S. chains choose us for rock-solid supply chains that handle Super Bowl-level surges without missing a beat.

Built Tough for Double Patties and Extra Sauce

Each fast food burger box uses thick 350gsm food-grade board with double-sided PE lamination and vented lids that prevent soggy buns. Our 120-person production team runs 24/7 shifts, ensuring 500,000-unit custom runs ship from China to California ports in just 8 days flat.

Branding That Turns First-Time Buyers into Loyal Fans

Transform ordinary cardboard into viral marketing with embossed logos, QR codes, and Instagram-worthy matte-black finishes. These fast food burger boxes use plant-based inks and recycled kraft, letting chains hit sustainability targets while driving 30% higher social media mentions per order.

Key Features & Benefits

✅ Double-layer grease barrier holds triple-cheeseburgers for 45 minutes without leakage

✅ Auto-lock bottoms withstand 4kg stacked in thermal delivery bags

✅ Served Lavazza USA drive-thru, Hangry Joe's nationwide, and Shokuh Dubai flagship stores

✅ One-piece clamshell design assembles in 2 seconds on high-speed lines

✅ Four Guangzhou plants output 4 million fast food burger boxes monthly

✅ FDA-approved microwave-safe up to 600W for 3 minutes with zero warping

FAQs

It’s made from durable, food-safe kraft or white paperboard, designed to maintain burger freshness and prevent sogginess during transport.

Absolutely — we can print your logo, colors, and tagline to create a consistent brand experience for every customer.

All-round Custom Options

Explore More Packaging Solutions

Check out matching fry cartons, chicken wing buckets, pizza sleeves, and cold-cup sleeves all produced under the same 25-year quality promise.

Disposable Cups

Custom hot & cold cups for cafes and QSRs, combining convenience with brand impact.

Paper Food Boxes

Grease-resistant boxes for Cake, burgers, noodles, and meals, secure and easy to carry.

Paper Bags

Eco-friendly takeaway bags with strong handles, ideal for bakery and retail branding.

Disposable Cups

Leak-proof bowls for soups, salads, and rice, perfect for dine-in or delivery.

Paper Food Buckets

Sturdy buckets for fried chicken, popcorn, or family meals, built for big portions.

Eco-friendly Packaging

Sustainable packaging made from compostable materials, designed to protect food and the planet.

Showcase of Success Stories

Lavazza Coffee drive-thru USA, Hangry Joe's 150+ locations, Sushi Bar ghost kitchens, and Shokuh premium desserts in Dubai count on our fast food burger boxes for flawless execution.

Packaging Upgrade for Lavazza’s U.S. Franchise Expansion

We supported Lavazza, a world-renowned specialty coffee chain, in upgrading its franchise packaging for the U.S. market. The new solution delivered consistent brand identity, sustainable materials, and improved functionality, helping their franchises enhance customer experience and meet local standards.

Customized Takeout Packaging for U.S. Sushibar Chain

We partnered with a U.S. sushi bar chain to solve challenges in their takeaway packaging. By providing tailored solutions, we reduced overall packaging costs while ensuring food safety, branding, and delivery efficiency.

Streamlined Overseas Packaging Procurement for Shokuh Patisserie

We supported Shokuh Patisserie, a luxury dessert brand from Dubai, in completing its first overseas packaging purchase. Our solution simplified the sourcing process, improved procurement efficiency, and helped reduce overall costs without compromising premium quality.

Complete Packaging Upgrade for Hangry Joe’s Expansion

We partnered with Hangry Joe’s, a U.S. fast-food chain, to upgrade their entire packaging line. The solution strengthened brand consistency, improved cost efficiency, and supported their rapid franchise growth.

Applications

Multi-Certifications for Trust

FDA Compliance

Packaging materials meet U.S. FDA requirements for safe food contact.

NSF Certified

Independent verification for food safety and public health compliance.

SIRA Tested

Products evaluated by recognized inspection and certification experts.

SGS Verified

Independent testing and verification by SGS to ensure quality and safety.

In-house Production Facility

1. Raw Material Management

We import only virgin pulp from SFI-certified forests, running burst-strength and Cobb tests every 4 hours to ensure every fast food burger box exceeds 300 kPa pressure resistance.

2. Printing & Production

Six Roland digital presses plus two 8-color offset lines print razor-sharp 1200 DPI artwork on 250,000 fast food burger boxes daily with perfect registration.

2. Printing & Production

Six Roland digital presses plus two 8-color offset lines print razor-sharp 1200 DPI artwork on 250,000 fast food burger boxes daily with perfect registration.

3. Quality Assurance

Inline vision cameras, X-ray contaminant detection, and third-party SGS audits every batch guarantee 99.99% defect-free fast food burger boxes before export.

4. Warehousing & Delivery

50,000㎡ bonded warehouses and pre-booked Evergreen shipping slots deliver containers to Long Beach, Savannah, and Jebel Ali in 7-9 days with 100% ETA accuracy.

4. Warehousing & Delivery

50,000㎡ bonded warehouses and pre-booked Evergreen shipping slots deliver containers to Long Beach, Savannah, and Jebel Ali in 7-9 days with 100% ETA accuracy.

Usually the MOQ of Custom Printed Takeaway Paper Bag is 5000pcs, but if you order more, the price would be more competitive.

Yes, we can make the bags based on your requirement. Like Handle Type, Size, Thickness and Printing can be customized, just Contact Us for further information.

We’re a direct factory with over 28 years experience in packaging & printing.

Yes, for sure we can send you some samples in stock by FREE, all you need to pay just the freight cost. If you need to customize the samples, please Contact Us for sample fee.