Ensuring Safety, Consistency & Reliability

At our manufacturing facilities, quality is built into every stage of production. From raw materials to final packaging, each batch of disposable food packaging undergoes rigorous inspections to ensure it meets global food safety, durability, and branding standards. Our QC process follows internationally recognized AQL inspection levels, supported by advanced testing equipment and trained specialists.

We verify the weight, coating, and certification of all incoming materials, ensuring they meet FDA, EU, and sustainability requirements for safe food contact.

Every printed design is tested for color accuracy, alignment, and ink adhesion using CMYK and Pantone standards to guarantee vibrant and lasting branding.

Dimensions, folding lines, and sealing strength are measured to maintain product consistency and prevent leakage or deformation.

Leak-proof, oil-resistant, and temperature endurance tests are conducted to ensure the packaging performs reliably during transport and use.

Before shipment, random samples are inspected under AQL standards for appearance, packaging integrity, and correct labeling, ensuring customer satisfaction.

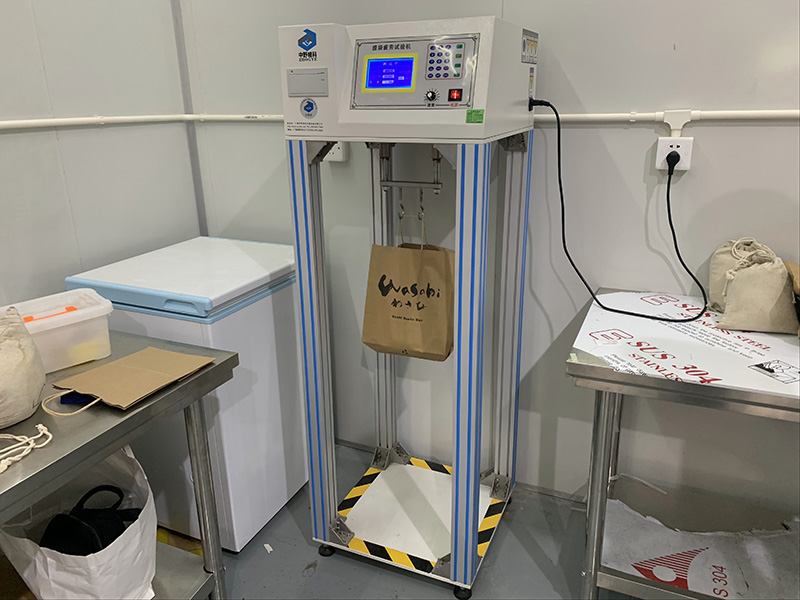

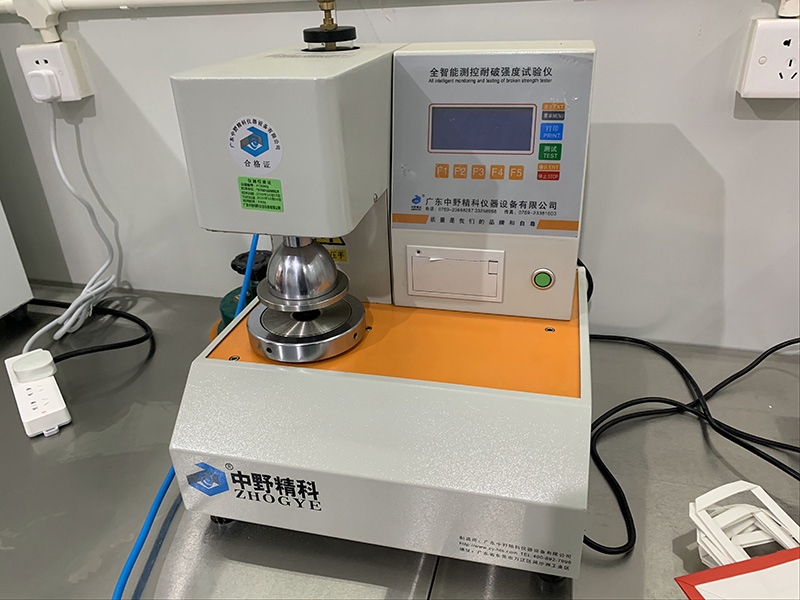

Advanced Testing Equipment & Controlled QC Environment

Our quality control laboratories are equipped with precision testing instruments and maintained in clean, controlled environments. From color accuracy measurement to leak-proof and durability testing, every piece of equipment is calibrated to international standards, ensuring consistent and reliable results for every batch of packaging we produce.