1. Background

Our client is the founder of a creative design agency based in the United States. Her company works closely with emerging consumer brands, providing end-to-end services—from brand creation and packaging design to product sourcing and supplier coordination.

This project began in August 2024 with what seemed like a standard inquiry for custom paper boxes. However, the end client behind the project was a first-time brand founder building her first product line. For her, packaging was not just a container—it was a critical part of her brand identity and customer experience. Every structural detail, material choice, and visual finish needed to support a premium brand image.

Over more than a year of collaboration, MaiBaoPak (MBP) provided technical guidance, material optimization suggestions, and consistent follow-up to support the client’s decision-making process. The project ultimately progressed smoothly from sampling to mass production.

2. The Challenge

This project presented several layered challenges:

2.1 First-time brand owner with high caution and expectations

The end client had little experience with custom packaging and was understandably cautious. She required multiple rounds of sampling and detail confirmation, making patience, clarity, and precision essential.

2.2 Complex design and technical requirements

The packaging design involved full-coverage metallic effects, fine-line graphics, and a custom EVA insert. These elements placed high demands on material selection, printing accuracy, production stability, and cost control. Even minor deviations could impact both visual quality and budget.

2.3 Strong competition from multiple suppliers

The client compared samples from several factories. MBP needed to stand out not only on price, but on professionalism, solution quality, and execution reliability.

2.4 Long project cycle with external uncertainties

The timeline was extended due to repeated design revisions, uncertain U.S.–China tariff conditions, and a slow final decision process. Maintaining momentum, trust, and engagement throughout this period was a critical challenge.

3. Solution by MBP

MBP adopted a guided-service approach, breaking down each decision—from structure and materials to finishing techniques—into clear, manageable steps. Through real samples, structural drawings, and clear process explanations, we helped the client understand the impact of each choice on performance, appearance, and cost, even without prior packaging experience.

3.1 Proactive risk assessment and material optimization

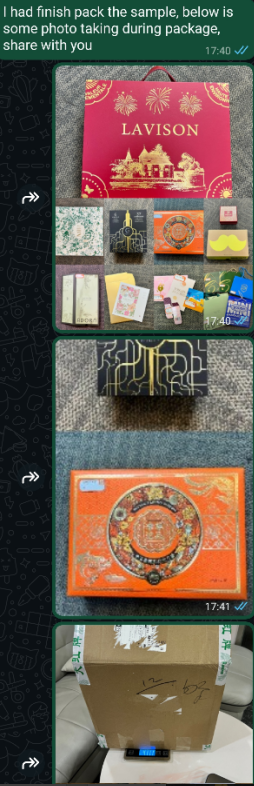

MBP identified potential production risks early and proposed optimized solutions. For example, we replaced a full hot-foil stamping design with silver board printed in a gold effect. This maintained a premium metallic appearance while improving cost efficiency and production stability. Fine-line designs that risked misalignment were also adjusted to ensure consistency in mass production.

3.2 Value-based comparison beyond pricing

Instead of simply providing quotes, MBP clearly demonstrated the differences between structural options, materials, and finishing techniques. This allowed the client to see how quality, durability, and long-term cost varied across solutions—helping them recognize MBP’s professional advantage beyond price alone.

3.3 Consistent, pressure-free project follow-up

Throughout the long project cycle, MBP maintained a steady communication rhythm—sharing industry insights, updated samples, production timelines, and decision checkpoints. Even during internal team transitions, MBP ensured seamless handover so that the client experience remained uninterrupted and reliable.

4. Why the Client Chose MBP

4.1 Practical, production-ready solutions—not just products

Faced with complex metallic finishes and structural demands, MBP provided material substitutions, process optimizations, and risk forecasts that preserved visual impact while ensuring cost control and production reliability.

4.2 High responsiveness and execution across multiple sample rounds

The client was willing to invest in multiple sample rounds to achieve the desired result. MBP responded quickly to each revision request and executed changes precisely, building confidence in the controllability of the final outcome.

4.3 Trust built through long-term consistency

Despite personnel changes on MBP’s side, the project continued smoothly with complete information continuity and consistent service quality. This stability reinforced the client’s trust throughout the extended decision-making process.

4.4 Clear demonstration of expertise through live communication

MBP conducted video meetings with both the intermediary and end client to present samples, materials, and technical solutions. Seeing the team, the samples, and the process firsthand helped the end client confirm that MBP was the strongest manufacturing partner for the project.

5. Results

5.1 Successful transition from sampling to mass production

After multiple rounds of testing and design optimization, the client finalized the packaging solution and moved smoothly into bulk production. MBP’s structural and material strategies ensured stable production, consistent quality, and on-target visual performance.

5.2 Enhanced brand image and customer experience

The high-end look and refined construction of the packaging helped the brand stand out during its store launch. The metallic finishes and custom EVA insert elevated both brand recognition and the unboxing experience, positioning the brand as premium and professional in a competitive market.

5.3 Strong client satisfaction and long-term partnership foundation

Both the intermediary and end client expressed strong appreciation for MBP’s expertise, patience, and continuous support. They noted that MBP delivered not only functional packaging, but also strategic value that exceeded expectations—laying the groundwork for ongoing collaboration.

6. Call to Action

Looking for a packaging partner who guides you from concept to production with clarity, stability, and real-world expertise?

Visit www.maibaopak.com to explore how MBP can support your next packaging project.

Post time: Jan-29-2026