Background

This project began with a direct client from South Africa. The main contact was not the business owner, but a senior decision-maker closely involved in daily operations and brand planning. The client operates four stores under a fast-growing brand that combines supermarket retail, bakery, ready-to-eat foods, and takeaway service — a hybrid model that is still relatively new in the local market.

At the time of contact, the client’s custom packaging volume was not yet large. However, they had clear expansion plans: two additional comprehensive supermarkets were scheduled to open by the end of the year. This meant one thing — packaging that worked for one store would soon need to scale across multiple locations, categories, and use cases.

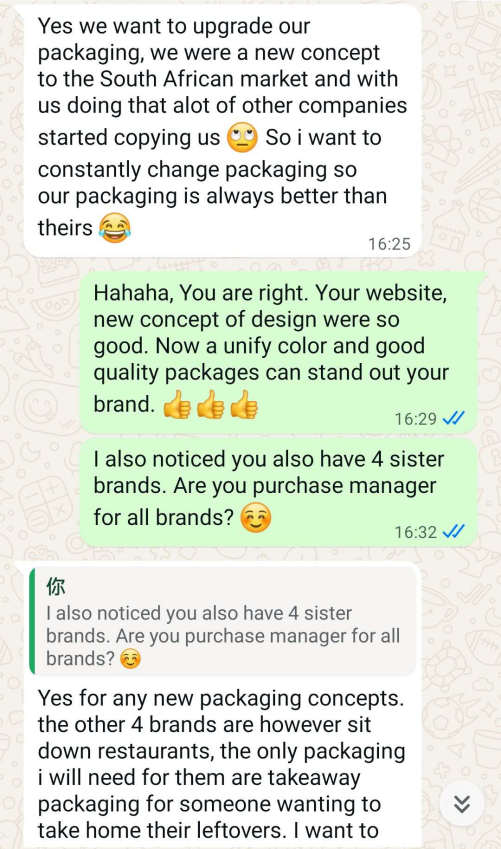

The client originally found MBP through Google while searching for better packaging solutions. Their motivation was straightforward but critical: local South African packaging suppliers could no longer meet their expectations. Quality inconsistency, rough finishing, and limited structural options were holding the brand back. At the same time, the client’s innovative business model was already being copied by competitors. To stay ahead, they needed packaging that could evolve continuously — not something static or easily replicated.

For this brand, packaging was no longer a basic operational cost. It was becoming a strategic tool for brand differentiation, store standardization, and long-term growth.

The Challenge

1. Local packaging quality could not support brand upgrading

Previously, the client sourced custom packaging locally in South Africa. While this approach offered convenience, the results were disappointing. Print quality varied from batch to batch, material stability was poor, and structural details lacked refinement. For a brand positioning itself as modern and premium, the packaging felt outdated and unpolished.

As store numbers increased, these flaws became more visible. The client needed packaging that looked consistent across all locations — packaging suitable for a chain brand, not a single independent shop. Without this, brand upgrading would remain impossible.

2. A growing brand facing fast imitation

As one of the earlier players combining retail, deli, bakery, and takeaway into one format, the client quickly attracted attention. Competitors began copying not only the business concept, but also visual elements.

This created a new requirement: packaging could not be a one-off success. It needed to be continuously upgradable — new structures, improved materials, refined visuals — so the brand could stay one step ahead instead of being trapped by old designs.

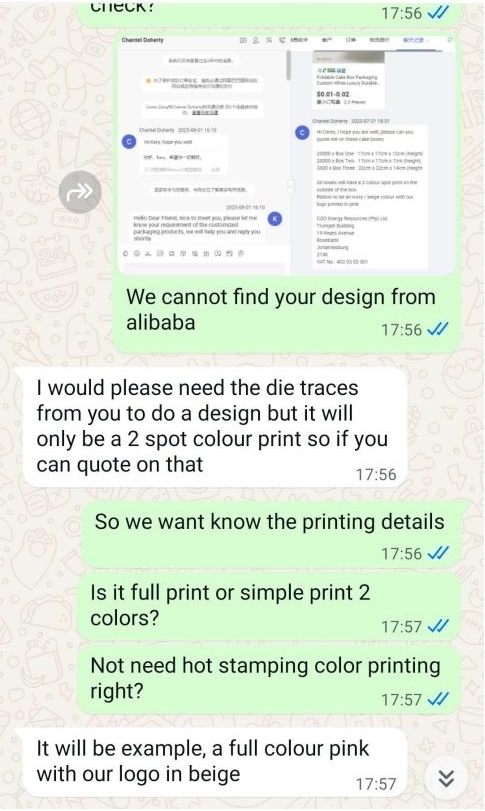

3. Design in progress, but professional support urgently needed

The client already had a clear customization direction: box styles, sizes, quantities, and full-coverage two-color printing. However, the final designs were still under development.

What they needed from a supplier went far beyond pricing and production. They required:

Accurate dielines to avoid redesign and rework

Structural recommendations matched to real food use scenarios

Risk warnings for full-coverage two-color printing

Guidance on color consistency and final print appearance

In short, the client needed professional support from design to finished product — not just a factory waiting for files.

The MBP Solution

1. A unified, chain-ready packaging system

Instead of immediately pushing quotations, MBP started by evaluating whether the client’s existing ideas could truly support long-term chain expansion.

We proposed a more stable, standardized packaging system designed specifically for multi-store use:

Food-grade materials with better stiffness and print stability

Paper types suitable for full-coverage printing

Structural adjustments to prevent deformation and glue failure during transport

Unified size logic across the product series to support future store openings

The goal was not just to make packaging look better, but to make it work reliably across scale.

2. Long-term, upgrade-friendly collaboration — not a one-time order

MBP treated this project as the foundation of an ongoing partnership. Beyond the current order, we helped the client:

Plan packaging needs for future store expansion

Reserve space for future visual updates and new box styles

Explore premium and sustainable material options for future launches, such as textured paper and food-sealing bag series

Packaging became a competitive barrier — not a cost easily copied by others.

3. Proactive design-to-production support

Even before final designs were confirmed, MBP actively supported the client with:

Precise dielines to ensure smooth design execution

Structural advice on creasing, windows, and assembly

Clear risk alerts and optimization suggestions for two-color full-coverage printing

By solving problems at the design stage, we helped the client avoid costly mistakes later and ensured the finished products were right the first time.

Why the Client Chose MBP

1. A clear positioning from the very first conversation

From the first contact, MBP made one thing clear: we are not just a packaging supplier — we are a brand packaging solution partner.

In the initial video call, we did not focus on individual products. Instead, we presented a lightweight, scalable packaging strategy: fewer materials, fewer SKUs, but full coverage across the product range. This approach reduced future procurement complexity and supported rapid store replication.

The client quickly realized they were not talking to a factory selling boxes, but to a team capable of accelerating brand growth.

2. Professional guidance for a brand’s first large-scale customization

This was the client’s first time handling large-scale custom packaging. Internally, they lacked professional packaging procurement experience and were unfamiliar with industry standards.

MBP did not simply ask for artwork and send a quote. We guided the client through:

Material selection trade-offs

Printing style comparisons

Series size planning

Cost structure and scalability considerations

By providing benchmarks, examples, and decision frameworks, we helped the client make informed choices quickly — saving weeks of internal discussion.

3. Real people, real communication — not email-only service

MBP insists on face-to-face video communication. Instead of sending only PDFs and quotations, we showed real samples, real processes, and real team members.

The client could clearly see who was responsible for their brand — a professional, responsive team that cared about outcomes. Despite being in different countries, the experience felt transparent, trustworthy, and collaborative.

4. Proactive, cross-team execution

While many suppliers wait passively for confirmation, MBP treats every step as a joint decision point. Design, sampling, materials, printing, and expansion planning were handled through close collaboration between sales, design, technical, and sourcing teams.

No unclear decisions were left unresolved before ordering. Trust was built not through persuasion, but through consistent proof.

Results & Feedback

1. From cautious evaluation to deep trust

Through multiple rounds of comparison, optimization, cost evaluation, and live video communication, the client’s core team moved from cautious observation to full confidence.

They recognized MBP not only as capable, but as faster, more professional, and easier to work with. The client proactively expressed interest in expanding cooperation into more product categories.

2. Faster store expansion through standardization

This collaboration helped the client establish a unified packaging system suitable for bakery, deli, and retail scenarios. Lighter structures, flexible order quantities, and high-recognition printing allowed new stores to replicate quickly.

As the client stated, “With a simplified packaging system, expanding stores feels much more manageable.”

3. Organic referrals driven by real experience

After testing and rollout, the client openly shared: “I’m willing to introduce you to more peers and friends in South Africa.”

This kind of referral — driven by genuine satisfaction — is the strongest validation of MBP’s value.

If your brand is preparing to scale, upgrade, or differentiate through packaging, MBP is ready to support you — from concept to execution.

Visit www.maibaopak.com to explore how we help growing brands build packaging systems that last.

Post time: Dec-16-2025