Paper, plastic, PLA, kraft—on the surface, food packaging materials look similar. But in real-world use, choosing the wrong option often leads to leaking containers, soggy food, failed deliveries, or products that don’t survive transport.

Many food brands source their food packaging supplies based on habit, price, or appearance, only to discover later that the material does not perform under real conditions.

Why does one package work perfectly for a hot meal, while another fails during delivery?

Why does “eco-friendly” packaging sometimes cost more but still cause customer complaints?

The truth is that food packaging materials behave very differently under heat, cold, moisture, and pressure. Without understanding these differences, packaging decisions become guesswork instead of strategy.

1. Classification of Food Packaging Materials

Food packaging materials can be broadly categorized based on their raw materials, performance properties, and environmental impact.

1.1 Paper-Based Food Packaging Materials

Paper-based materials are widely used in paper cup packaging, including paper coffee cups and disposable paper cups for food & beverage, especially for hot drinks, cold beverages, and single-serve applications. They come from wood fibers and include cardboard, kraft board, and coated papers. These materials are lightweight and offer excellent printability, making them ideal for boxes used in dry foods like cereals, cookies, and baked goods. Paper packaging allows breathability, which helps prevent moisture buildup in certain products. However, without treatment, it absorbs liquids easily, so coatings are often added for better water resistance. In recent years, the use of recycled paper has increased significantly, helping conserve resources and appeal to eco-conscious consumers.

1.2 Kraft Paper Food Packaging

Kraft paper is produced using the sulfate process, which preserves long fibers and gives the material superior strength and tear resistance. It typically features a natural brown appearance that conveys an eco-friendly, minimalist aesthetic.

Kraft paper is widely used for paper food boxes, takeaway food containers, anddisposable food packaging boxes in the foodservice industry. Its strength and tear resistance make it suitable for both dine-in and takeaway applications.

When coated, kraft paper provides effective grease resistance, making it ideal for oily foods such as fried chicken, burgers, and pastries. It is biodegradable and recyclable, making it a preferred choice for brands focused on sustainability.

1.3 Plastic Food Packaging Materials (PE and Related Types)

Polyethylene (PE) is one of the most common plastics in food packaging, including low-density PE (LDPE) and high-density PE (HDPE). PE films are flexible and resistant to low temperatures, commonly used for freezer bags, cling wraps, and bottles. They provide excellent barriers against moisture and oxygen, keeping food fresh longer at a low cost. PE is suitable for fresh produce, meats, and frozen products. Multi-layer PE composites further enhance preservation capabilities.

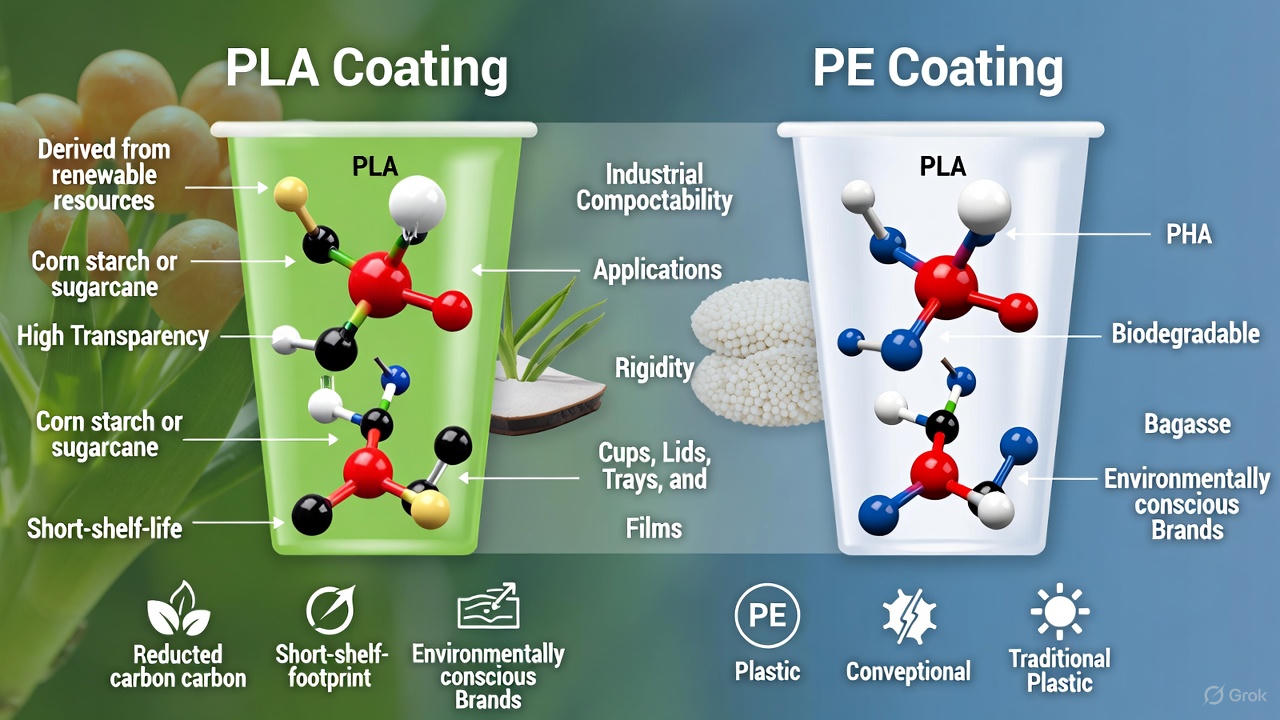

1.4 Biodegradable Food Packaging Materials (PLA and Alternatives)

Polylactic acid (PLA) is derived from renewable resources like corn starch, making it a leading biodegradable plastic alternative. It offers high transparency similar to traditional plastics and is used for cups, trays, and films. PLA can break down in industrial composting facilities, reducing long-term environmental impact. Other alternatives include PHA (polyhydroxyalkanoates) and starch-based materials, ideal for short-shelf-life foods.

To better navigate these differences, it’s useful to compare specific material categories in depth. For example, this paper vs plastic food packaging guide breaks down performance and sustainability trade-offs between paper, PE, and hybrid materials, while this compostable vs biodegradable article helps clarify which eco-friendly packaging claims truly hold up in practice.

1.5 Other Common Food Packaging Materials

In addition to the main categories, other materials are used for specific applications:

- Aluminum foil provides excellent barrier properties for long-shelf-life and sterilized foods.

- Glass packaging offers premium protection, chemical stability, and high-end appeal.

- Composite materials combine paper, plastic, and aluminum layers for vacuum packaging, aseptic cartons, and cans.

2. Food Safety and Protection from Packaging Materials

One of the primary functions of food packaging is to protect food from external factors that can affect quality and safety.

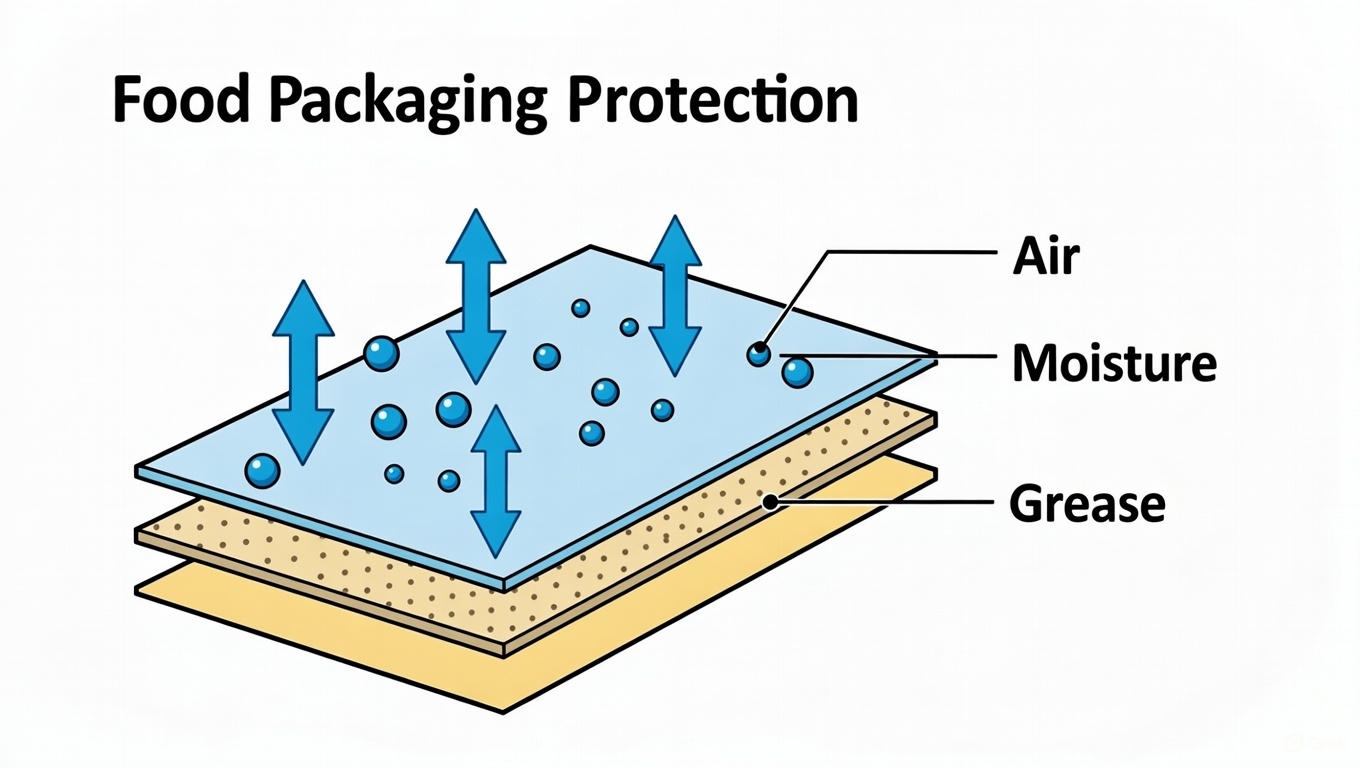

2.1 Barrier Against Air, Moisture, and Grease

Food packaging materials must create effective barriers to protect contents from external elements like oxygen, water vapor, and grease. Oxygen exposure can cause oxidation, leading to rancidity in fats and loss of flavor in many products. Moisture barriers prevent sogginess in dry goods or drying out in moist items, while grease resistance is crucial for fried or oily foods.

Polyethylene (PE) excels here with its strong moisture and oxygen barrier properties, making it ideal for fresh produce and frozen items. Paper-based materials often require coatings, such as wax or polymer layers, to achieve similar protection without becoming soggy. Kraft paper, when coated, offers good grease resistance for takeout foods. PLA provides moderate barriers but performs well in short-shelf-life applications. Multi-layer composites combine these strengths for optimal protection. Overall, the choice of barrier depends on the food type and required shelf life.

2.2 Preventing Contamination During Storage and Transport

Packaging plays a key role in shielding food from physical damage, dust, insects, and microbial contamination throughout the supply chain. Strong materials like kraft paper resist tears and punctures during handling and shipping. Sealed PE bags block external contaminants effectively, especially in vacuum or modified atmosphere packaging (MAP) that removes oxygen to inhibit bacterial growth. Paper packaging allows some breathability, which benefits fresh produce by preventing mold, but needs careful sealing. Coatings on kraft or paper enhance durability against impacts. Transportation stresses, such as stacking or temperature fluctuations, require robust designs to maintain integrity. Proper sealing techniques, like heat sealing for plastics, ensure no entry points for pollutants. In global supply chains, compliant packaging reduces risks of recalls due to contamination.

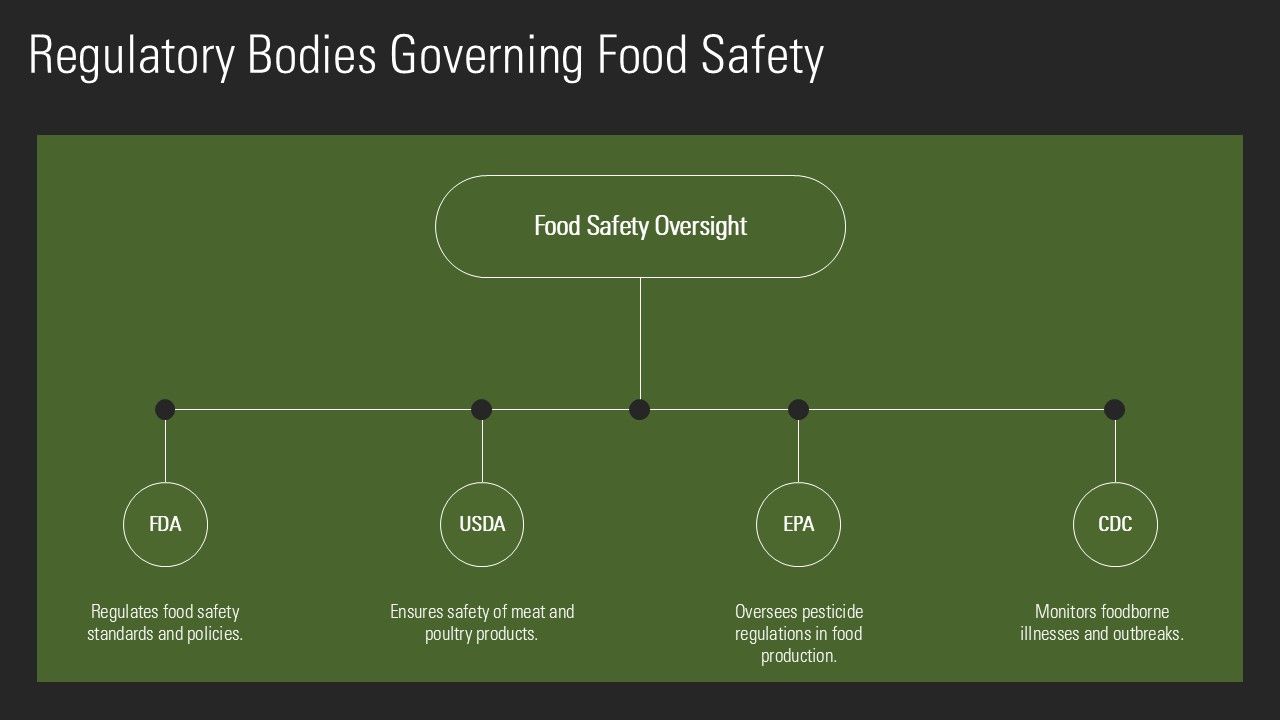

2.3 Food-Grade Standards and Compliance

Food packaging materials must meet stringent regulatory standards to prevent the migration of hazardous substances.

- United States: FDA 21 CFR regulations require food contact materials to be safe and compliant.

- European Union: (EC) No 1935/2004 and (EU) No 10/2011 regulations regulate food contact plastics and are scheduled for update in 2025, further tightening chemical restrictions.

- China: The GB 4806 series of standards regulate food contact materials.

PFAS and other hazardous substances are subject to increasingly stringent restrictions globally. Manufacturers must provide a Declaration of Compliance (DoC) and conduct migration testing to ensure product safety.

3. Sustainability and Environmental Impact of Food Packaging Materials

3.1 Recyclable and Compostable Packaging Materials

Recyclability and compostability are central to sustainable packaging. Paper and kraft paper are highly recyclable, with established global recycling streams reaching over 80% in some regions. PLA is industrially compostable, breaking down in facilities but not always in home setups. Bagasse from sugarcane is both recyclable and compostable. Mono-material designs, like pure PE, improve recycling rates over composites. Certifications like EN 13432 for compostability guide proper disposal. Many brands shift to these to meet circular economy goals. Challenges include contamination in recycling streams from food residues.

3.2 Reducing Plastic Waste in Food Packaging

Traditional plastics contribute significantly to global waste, prompting reductions through alternatives and regulations. The EU’s PPWR in 2025 mandates recyclability and reuse targets, cutting single-use plastics. Brands adopt bio-based options to lower fossil fuel dependency. Extended Producer Responsibility (EPR) laws in multiple countries make companies accountable for end-of-life management. Innovations like thinner films reduce material use while maintaining performance. Consumer pressure drives reusable systems in foodservice.

3.3 Environmental Impact Comparison by Material Type

Life-cycle assessments compare impacts across materials. Paper and kraft have lower carbon footprints but higher water usage in production. PE relies on fossil fuels, leading to persistent pollution and higher greenhouse gases. PLA from renewable sources reduces emissions but requires industrial composting for full benefits. Studies show biodegradables like PLA-coated kraft can have lower overall impacts when properly disposed. Recycled content further lowers footprints for all types.

3.4 Trends Toward Greener Food Packaging Solutions

In 2025, trends include mono-materials for easier recycling, algae-based plastics, and smart coatings for better barriers. Edible films and antimicrobial additives extend shelf life, reducing food waste. Regulations like EU PPWR and US EPR accelerate adoption. Consumer demand for transparency pushes traceable, certified sustainable options.

| Material | Renewable Source | Recyclable | Compostable | Environmental Notes |

| Paper | Yes | Yes | Sometimes | Needs coating removal |

| Kraft | Yes | Yes | Sometimes | Strong fibers |

| PE | No | Limited | No | Fossil-based |

| PLA | Yes | No | Yes (industrial) | Needs composting facility |

| Bagasse | Yes | No | Yes | Low carbon footprint |

4. Performance and Practical Applications of Food Packaging Materials

4.1 Strength and Structural Durability

Durability ensures packaging withstands handling and stacking. Kraft paper offers superior tensile strength, ideal for heavy or bulky items. PE is flexible and impact-resistant, preventing breaks in transport. Paper needs reinforcements for load-bearing. Cold conditions test brittleness, where PE performs best.

4.2 Heat and Cold Resistance for Different Foods

Temperature tolerance varies widely. PE handles extremes from -40°C freezing to moderate heat. PLA limits to about 50°C, unsuitable for hot fills or microwaving. Coated kraft suits hot greasy foods but not extremes.In hot beverage applications, paper cup packaging often relies on inner coatings to withstand heat and prevent leakage, especially in coffee and tea service. Matching material to food temperature needs preserves quality.

4.3 Cost Comparison of Packaging Materials

Costs differ significantly in 2025. Traditional PE remains cheapest due to scale and fossil sources. Paper and kraft are mid-range, affordable for many applications. PLA is 2-4 times more expensive than PE, though prices drop with production growth. Long-term, sustainable options save on waste fees and appeal to consumers.

4.4 Best Packaging Materials for Different Food Types

Dry goods like cereals suit breathable paper boxes. Fresh produce needs perforated PE bags for ventilation. Frozen foods require durable PE films. Greasy takeout favors coated kraft or PLA-lined paper. Beverages often use composites for barriers.For bakery items, snacks, and light meals, paper packaging bags and kraft paper bags for food offer a balance of strength, breathability, and sustainability.

5.Advantages and Disadvantages of Main Food Packaging Materials

5.1 Paper Packaging: Advantages and Limitations

Paper is lightweight, printable, and highly recyclable from renewable sources. It offers good breathability for produce and low cost for dry goods. However, it absorbs moisture easily without coatings, has lower strength, and may require additives for barriers. Recycled paper reduces resources but needs careful sourcing for food safety.

5.3Kraft Paper: Strengths and Weaknesses

Kraft’s high strength and tear resistance come from its sulfate process, making it durable for bags and boxes. Its natural look appeals for branding, and it’s biodegradable/recyclable. Coatings add grease resistance. Weaknesses include limited waterproofing without treatment and fewer color options.

5.4 PE Plastic: Benefits and Drawbacks

PE provides excellent barriers, flexibility, low cost, and temperature resistance, ideal for diverse foods. It’s lightweight and sealable. Major drawbacks are non-biodegradability, fossil fuel origin, and contribution to microplastics pollution.

5.5 PLA Packaging: Pros and Cons

PLA from corn starch is renewable, compostable in facilities, and transparent like PET. It reduces carbon emissions and is food-safe. Cons include higher cost, limited heat resistance, and need for industrial composting—not home or landfill degradation.

5.6 Quick Comparison Table for Food Packaging Materials

Key differences include: Cost—PE lowest, paper/kraft medium, PLA highest. Sustainability—PLA and kraft highest, PE lowest. Barriers—PE strongest, others need coatings. Temperature—PE widest range.

| Material | Main Advantages | Key Limitations |

| Paper | Lightweight, printable | Needs coating |

| Kraft | Strong, natural look | Limited liquid resistance |

| PE | Excellent barrier | Environmental concerns |

| PLA | Renewable source | Composting required |

6.How to Choose the Right Food Packaging Material

6.1 Key Factors to Consider When Selecting Materials

Factors include food type (dry, wet, frozen), shelf life needs, barrier requirements, cost budget, and sustainability goals. Regulatory compliance, transport durability, and consumer preferences also matter. Testing for migration and performance ensures safety.

6.2 Matching Packaging Materials to Food Needs

Dry snacks fit paper/kraft for breathability. Moist/frozen items need PE barriers. Short-life eco products suit PLA. Branding-focused choose kraft’s natural aesthetic.

6.3 Balancing Food Safety, Sustainability, and Cost

Prioritize safety via certifications. Opt for hybrids like PLA-coated kraft for eco-benefits without full cost jump. Bulk sourcing and scale reduce expenses while meeting green targets.

7. The Future of Food Packaging Materials

7.1 Innovations in Packaging Materials

Emerging include algae/plant-based bioplastics, nanotechnology for enhanced barriers, and smart indicators for freshness. Edible coatings and reusable systems gain traction.

7.2 Evolving Regulations and Compliance Requirements

2025 sees stricter plastic limits via EU PPWR, US EPR expansions, and global PFAS bans. Recycled content mandates and compostability standards push innovation.

7.3 Changing Consumer Expectations

Consumers demand transparent, minimal, and green packaging. Surveys show willingness to pay premiums for sustainable options, influencing brand choices.

8.Summary of Key Points

8.1 Main Insights on Food Packaging Materials

PE offers top performance at low cost but lacks sustainability. Paper and kraft provide balanced, eco-friendly options. PLA leads in biodegradability despite higher costs. Future favors hybrids and innovations for safety and environment.

8.2 Quick Reference Guide for Material Selection

- Budget-focused: PE or paper.

- Eco-priority: PLA or kraft.

- High performance: Multi-layer PE.

- Hybrid approach: PLA-coated kraft.

As food brands grow and diversify their product lines, standard packaging solutions are often no longer enough. More businesses are turning to custom food packaging to better match their specific food types, portion sizes, branding needs, and sustainability goals.

Custom solutions allow brands to optimize material selection, structural design, and performance requirements—whether for paper cups, takeaway containers, food boxes, or packaging bags—while ensuring compliance, consistency, and cost control across different markets.

9. Frequently Asked Questions About Food Packaging Materials

9.1 Which food packaging material is the most eco-friendly?

PLA and kraft paper rank highest—PLA for compostability and kraft for recyclability from renewable sources—depending on disposal infrastructure.

9.2 Is PLA better than traditional plastic packaging?

Yes for sustainability (degradable and renewable), but it costs more and has lower heat tolerance, best for short-shelf-life items.

9.3 Can paper packaging keep food fresh?

Coated paper effectively blocks moisture for dry and medium-shelf-life foods, though not as comprehensively as plastic.

9.4 Why is kraft paper so popular in food packaging?

Its high strength, natural look, eco-credentials, and moderate cost make it ideal for takeout and branding.

9.5 Are all food packaging materials safe for food contact?

No—not all. They must pass food-grade certifications (e.g., FDA or EU standards) to prevent harmful migration.

For more details, refer to authoritative sources like the FDA Food Packaging Guidelines or EU Food Contact Materials Regulations.

Post time: Dec-30-2025