Background: Meeting Tanya, a Co-Founder with Vision In May 2024, during the NRA Show in Chicago, MaiBaoPak (MBP) team met Tanya, the co-founder of several sushi restaurant chains across the U.S. As a key decision-maker for operations and packaging procurement, Tanya was exploring better solutions to support her rapidly growing restaurant business.

Tanya was impressed by our team’s professionalism and product quality at the show. After further learning about our past success stories through our website and social media, her interest in working with MBP grew stronger. She wasn’t just looking for a packaging vendor; she needed a reliable long-term partner that could deliver cost savings, quality control, and creative support.

The Challenge:High Costs, Low Control, and Uncertainty

Before MBP, Tanya was sourcing packaging from China through a local U.S. trading company. The pain points were clear:

1. Rising Costs: Procurement costs were high, yet packaging quality and functionality were inconsistent.

2. Lack of Direct Sourcing Experience: Tanya had never worked directly with a Chinese manufacturer. Concerns over tariffs, logistics, quality assurance, and post-sale support made her hesitant.

3. Food Safety: Sushi packaging requires direct food contact, so safety certifications were non-negotiable.

4. Brand Expansion Needs: Tanya needed solutions to improve cost-efficiency and enhance packaging creativity, especially for seasonal campaigns and promotional designs.

MBP’s Tailored Solution: Trust Through Transparency and Expertise

MBP addressed each challenge through a hands-on, data-driven approach:

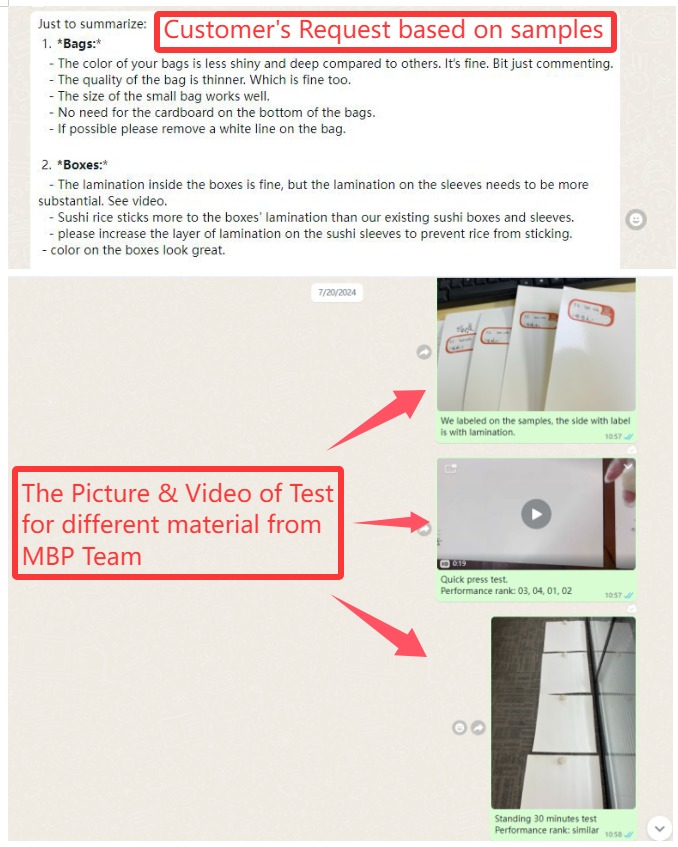

1. Customized Testing & Visual Assurance We presented a full-suite packaging proposal and conducted a comparative “30-minute sticky rice test” using four advanced coating options. The test was filmed and delivered as a video demo to help Tanya visualize performance outcomes. We also shipped multiple samples to allow hands-on validation of quality.

2. Door-to-Door Logistics with Zero Guesswork Understanding Tanya’s limited exposure to direct imports, our team provided full end-to-end guidance, including DDP (Delivered Duty Paid) logistics. From customs clearance to last-mile delivery, we made the entire process seamless. To boost confidence, we also shared references from U.S.-based clients in the same industry.

3. Certified Food-Safe Materials We provided FDA-compliant and SGS-tested materials to ensure our packaging met U.S. food safety regulations—a critical requirement for raw food service.

4. Smart Inventory and Brand Design Support Beyond physical packaging, we helped integrate MBP’s packaging inventory management system with the client’s ERP, enabling auto-restock reminders. Our in-house design team also created holiday-themed packaging designs that aligned with the client’s branding and customer experience goals.

Why Tanya Chose MBP: More Than a Vendor, a Growth Partner

1. Transparent Pricing, Proven Solutions MBP offered a bundled quote for a full range of packaging with no hidden costs. Our transparent approach and expertise in solving common quality issues stood out.

2. U.S. Market Know-How & Hands-On Guidance We delivered not just packaging, but peace of mind—walking Tanya through every step of the import process while reducing cost and time complexity through DDP service.

3. Compliance-Ready Products Our certifications minimized legal risks and ensured the restaurant group stayed compliant with local regulations.

4. Strategic Collaboration Tanya valued our vision of becoming a strategic growth partner. MBP’s ability to manage inventory and deliver creative packaging gave her brand a competitive edge.

The Result: Savings, Speed, and Long-Term Success

- 20% Cost Reduction: By switching to MBP, Tanya achieved a 20% reduction in packaging costs.

- 1/3 Faster Procurement: Our streamlined process shortened execution time by over 30%.

- Improved Packaging Performance: New materials delivered better functionality, improved food presentation, and elevated customer satisfaction.

- Brand Confidence: The partnership laid the foundation for ongoing expansion, with MBP positioned as Tanya’s go-to packaging partner.

Ready to scale your brand with smarter packaging?

Let’s talk about how MBP can power your packaging transformation.

Visit us at www.maibaopak.com

Post time: Aug-12-2025