You choose PLA cups because they look sustainable, sound responsible, and align with your brand’s commitment to the planet. But what if that “green” label doesn’t actually mean greener outcomes?

As more businesses turn to compostable and biodegradable materials in search of sustainable packaging solutions, many are discovering a troubling reality: products that appear eco-friendly on the shelf often fail to deliver real environmental benefits after disposal.

PLA (polylactic acid) cups are widely promoted as a better alternative to traditional plastic—but their true environmental impact depends not on what they’re made of, but on what happens after they’re thrown away.

1. How PLA Cups Are Made and Why They Seem Green

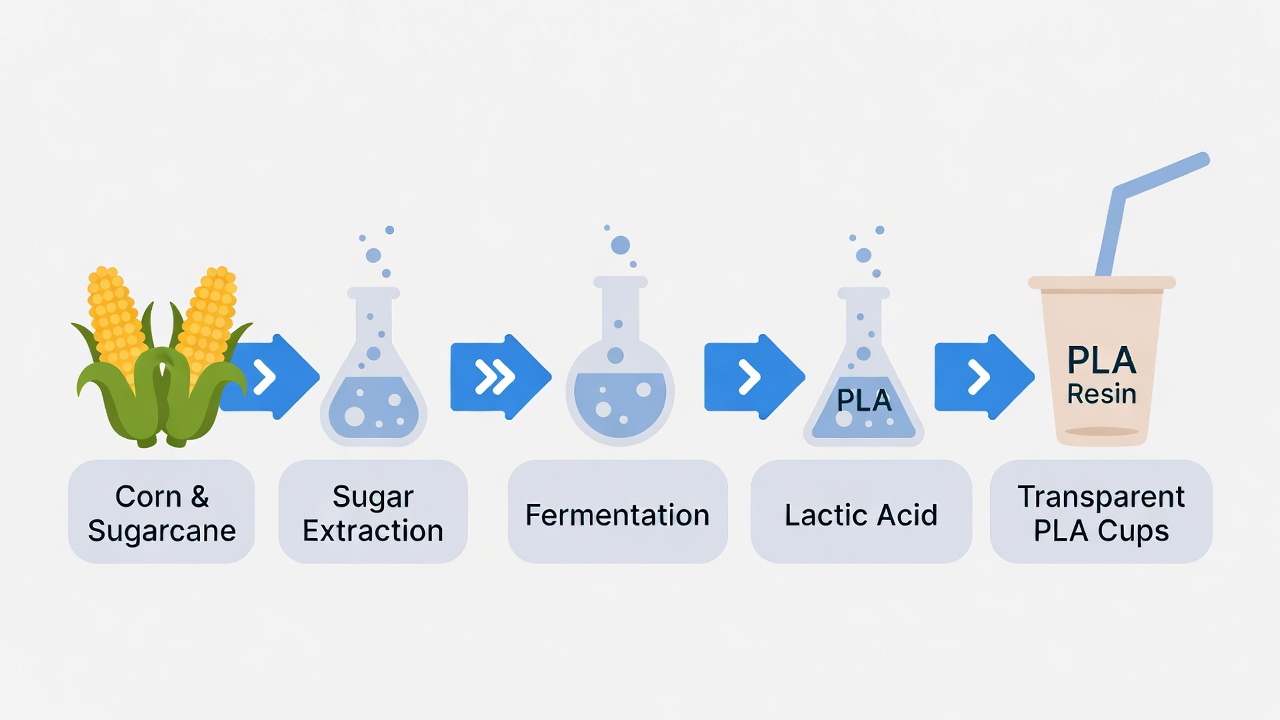

PLA, or polylactic acid, starts as a bioplastic derived from fermented plant sugars, most commonly from corn starch or sugarcane. This renewable origin gives PLA cups their “green” appeal, as they avoid direct reliance on petroleum-based feedstocks used in conventional plastics like PET or PP.

1.1. The Plant-Based Source of PLA

PLA stands for polylactic acid, a type of plastic made from plant sugars rather than oil. The most common raw materials are corn starch from the United States and sugarcane from other countries. Farmers grow these crops, harvest them, and send the starch or sugar to factories. There, the material is fermented by bacteria to produce lactic acid. This lactic acid is then chemically linked together to form long chains called PLA resin. Because the starting point is plants that grow every year, PLA is considered renewable instead of depending on limited fossil fuels. This renewable origin is one of the main reasons companies call PLA cups eco-friendly.

1.2. Lower Fossil Fuel Use in Production

Making regular plastic cups usually starts with drilling for oil, refining it, and using a lot of energy from fossil fuels. In contrast, PLA production uses much less oil-based energy because the main ingredient comes from plants. Studies that look at the entire production process (called life cycle assessments) often show that PLA creates 50% to 65% fewer greenhouse gas emissions during manufacturing compared to PET plastic. The plants grown for PLA also absorb carbon dioxide while they grow, which helps offset some of the emissions released later. This combination of renewable feedstock and lower fossil energy use gives PLA its strong “green” image in marketing materials.

2. The Big Promise: Biodegradability and Compostability

One of the biggest selling points of PLA cups is that they are marketed as compostable cups. However, compostability depends heavily on disposal conditions.

2.1. What Industrial Composting Really Requires

PLA is labeled “compostable,” but that label only applies under very specific conditions found in industrial composting facilities. These large-scale compost sites maintain steady high temperatures between 55°C and 60°C (131–140°F) for weeks. They also keep the right level of moisture, plenty of oxygen, and billions of active composting microbes. The material is turned regularly to mix everything evenly. Only when all these factors are controlled can PLA break down properly into water, carbon dioxide, and organic matter. Home compost bins or natural soil almost never provide these exact conditions.

2.2. How Long PLA Cups Take to Break Down in Ideal Conditions

When placed in a well-managed industrial composting facility, PLA cups usually start to break apart within a few weeks. Most certified PLA products reach at least 90% breakdown within 90 to 120 days under ideal heat, moisture, and microbe activity. After full decomposition, what remains is nutrient-rich compost that can be used to grow new plants. This closed-loop process—plant to cup to compost back to soil—is the main environmental promise of PLA. Certification standards like ASTM D6400 or EN 13432 test and confirm this performance in controlled industrial settings only.

Table: PLA Breakdown Time by Disposal Method

| Disposal Method | Breakdown Time | Effective Composting? |

|---|---|---|

| Industrial composting | 60–180 days | ✅ Yes |

| Home compost | Years / no breakdown | ❌ No |

| Landfill | Very slow (years+) | ❌ No |

| Ocean / environment | Extremely slow | ❌ No |

3. Real-World Challenges with PLA Disposal

Despite their compostable certification, most PLA cups never reach industrial composting facilities. This creates a major gap between environmental promise and environmental reality.

3.1. Why Most PLA Cups End Up in Landfills

Very few cities and towns have industrial composting programs that accept PLA items. Even when they do, the cups must be separated from regular trash and sent to the right facility. In practice, most people throw PLA cups into ordinary garbage bins. Waste collection trucks mix everything together, and sorting machines at recycling or waste plants often cannot tell PLA apart from other plastics. Because of these practical barriers, the majority of PLA cups worldwide end up in landfills instead of compost facilities, no matter what the label says.

3.2. Why PLA Doesn’t Work in Home Compost

Home compost piles usually stay much cooler than industrial ones, often between 30°C and 50°C at best. PLA needs consistent high heat above 55°C to soften and let microbes attack it effectively. Without that temperature, the material breaks into smaller pieces very slowly or not at all. Many people report finding PLA fragments still visible in their home compost after one or two years. In backyard settings, PLA tends to behave more like regular plastic than like food scraps or paper.

3.3. Methane Emissions Risks in Landfills

Landfills are dark, compacted, and low in oxygen. Under these anaerobic conditions, some organic materials release methane gas as they slowly break down. Although PLA is slower to degrade than food waste, it can still produce methane over many years in a landfill. Methane is a powerful greenhouse gas that traps heat much more effectively than carbon dioxide in the short term. While the amount from PLA is usually smaller than from food scraps, every bit of methane adds to climate change when thousands or millions of cups are landfilled every day.

4. PLA Cups vs Traditional Plastic Cups

To determine whether PLA cups are truly eco-friendly, it’s important to compare them with conventional plastic alternatives across multiple environmental dimensions.

4.1. Carbon Footprint and Greenhouse Gas Emissions

From the moment crops are planted until the PLA resin is made, the process usually creates fewer greenhouse gases than making PET plastic from oil. Many studies report 60–65% lower emissions for PLA production compared to PET when looking only at the manufacturing stage. However, if the PLA cup is not composted and instead goes to a landfill, some of those initial savings can be lost over time due to methane release. When full composting happens, the overall carbon footprint remains lower than most conventional single-use plastic cups. The advantage is clearest when comparing cradle-to-compost versus cradle-to-landfill scenarios.

4.2. Recycling Challenges and Contamination Risks

Traditional plastic cups made of PET or PP can sometimes be recycled if collected separately. PLA, however, looks similar but melts and behaves differently in recycling machines. When even a small amount of PLA gets mixed into a PET recycling batch, it can ruin the entire load by creating weak spots or discoloration in the new plastic. Because very few recycling plants accept PLA, almost all PLA cups are treated as non-recyclable in practice. This makes PLA harder to handle in current recycling systems than some fossil-based plastics.

4.3. Environmental Trade-Offs: Water Use, Land Use, and Agriculture

Growing corn or sugarcane for PLA requires large amounts of farmland, irrigation water, and fertilizers. These agricultural demands can lead to soil erosion, pesticide runoff into rivers, and competition with food crops in some regions. Studies show PLA production sometimes uses more water and land than making certain fossil plastics. Fertilizer runoff also contributes to algae blooms and dead zones in lakes and oceans. These indirect impacts mean that while PLA reduces oil use, it shifts some environmental pressure onto farming and freshwater systems.

Comparison Table: PLA Cups vs Traditional Plastic Cups

| Feature | PLA Cups | Traditional Plastic Cups |

|---|---|---|

| Raw Material | Plant-based (corn, sugarcane) | Fossil fuels |

| Compostability | Industrial compost only | Not compostable |

| Home Compost | ❌ No | ❌ No |

| Recycling Compatibility | Limited | Limited |

| Carbon Footprint (Production) | Lower | Higher |

| End-of-Life Impact | Low if composted; high if landfilled | High |

5. Pros and Cons of PLA Cups for Everyday Use

PLA cups offer both meaningful advantages and notable limitations for food service businesses and consumers.

5.1. Advantages of PLA Cups Over Conventional Plastic

PLA cups are made from plants that grow back every year, so they do not rely on extracting finite oil reserves. Their production usually creates lower greenhouse gas emissions than PET cups when measured from farm to factory. PLA is clear, strong for cold drinks, and approved for food contact. If the cups do reach an industrial composter, they turn into useful soil amendment instead of staying as waste forever. For businesses and consumers who value reduced fossil fuel use and have access to proper composting, PLA offers meaningful benefits over regular plastic.

5.2. Limitations and Practical Drawbacks

PLA cups soften and deform when exposed to hot liquids above about 60°C, so they cannot hold coffee or tea. They are also more brittle in very cold temperatures than some plastics. Most importantly, the lack of widespread industrial composting means the majority end up in landfills where they persist for a long time and may release methane. Growing the crops for PLA uses significant water, land, and fertilizers, creating other environmental costs. These practical and systemic limitations prevent PLA from being a complete solution to single-use plastic waste.

Simple pros and cons table for quick reference:

| Pros of PLA Cups | Cons of PLA Cups |

|---|---|

| Renewable plant-based material | Cannot handle hot drinks (softens >60°C) |

| Lower production emissions (50–70% less CO₂ vs PET) | Most end up in landfills, not composted |

| Breaks down in industrial compost (90–180 days) | Requires special high-heat facilities |

| Clear and food-safe for cold drinks | Higher water/land use from farming |

| Reduces fossil fuel dependence | May release methane in landfills |

6. Final Verdict: Are PLA Cups Truly Eco-Friendly?

PLA cups are not a silver bullet—but under the right infrastructure, they can reduce environmental impact compared to conventional plastics. Without access to industrial composting and proper disposal systems, however, their benefits remain largely theoretical.

For brands committed to genuine sustainability, the key is not simply choosing “green-looking” products, but partnering with responsible food packaging suppliers who understand material science, waste systems, and regulatory compliance—and can help match the right packaging to real-world conditions.

7. Frequently Asked Questions (FAQ)

7.1 Can PLA cups go in home compost?

No. PLA cups require industrial composting conditions and will not break down in home compost bins or backyard compost piles.

7.2 Are PLA cups better than paper cups lined with plastic?

It depends. PLA cups may offer lower production emissions, but paper cups with plastic linings are often easier to dispose of in existing waste systems. Neither option is perfect.

7.3 Do PLA cups break down in oceans or landfills?

No. PLA cups do not break down effectively in marine environments or landfills and may persist for years.

7.4 How much lower is the carbon footprint of PLA cups?

PLA cups generally have a lower carbon footprint during production compared to petroleum-based plastics. However, the overall impact depends heavily on disposal method—industrial composting versus landfill.

7.5 How should businesses choose truly sustainable cup materials?

Businesses should consider material performance, disposal infrastructure, certifications, and supplier transparency—not just compostable labels.

Post time: Feb-04-2026